PC

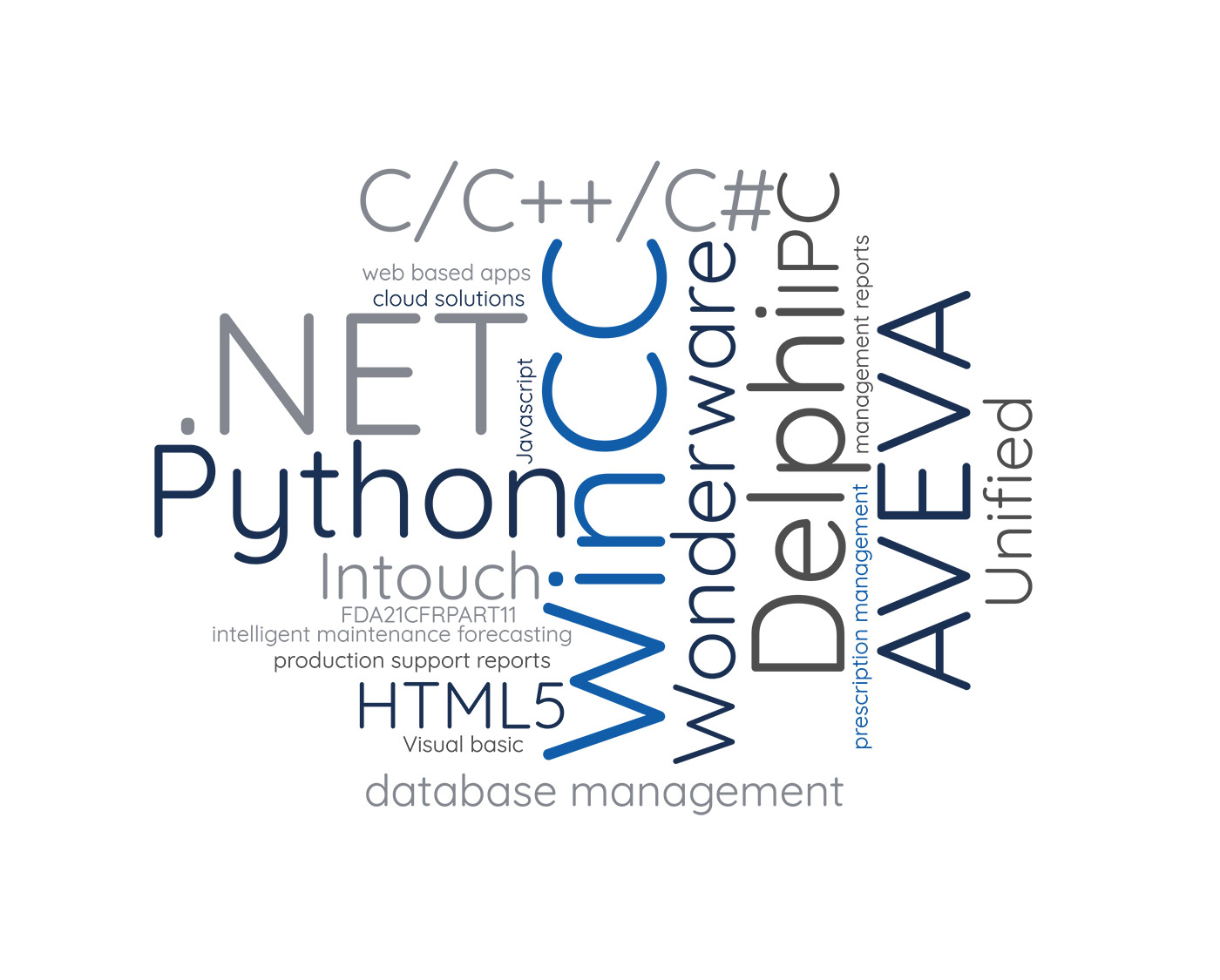

Since our establishment in 1989, it has been our primary goal to ensure that our software systems fully meet the individual needs of our clients. We consistently strive to employ the latest proven technical solutions. As a result, we've had the opportunity to gain significant experience with various programming languages (C, C++, C#, .NET, VBS, Python), numerous SCADA systems (such as WinCC V5 to V7.5, Wonderware – AVEVA - Intouch), HMI systems (ProTool, WinCC Flexible, TIA PORTAL WinCC, TIA PORTAL WinCC Unified), and other development environments (Delphi, Qt). Our utilized and applied database management systems include Firebird, Access, Microsoft SQL. Our latest PC-based systems are built on Siemens WinCC V7.5, utilizing web-based administration applications resting on JavaScript, Python, and HTML foundations, alongside MS SQL databases.